Raglan boutique brewers Workshop Brewing Company are making a big impact with their small batch craft beers.

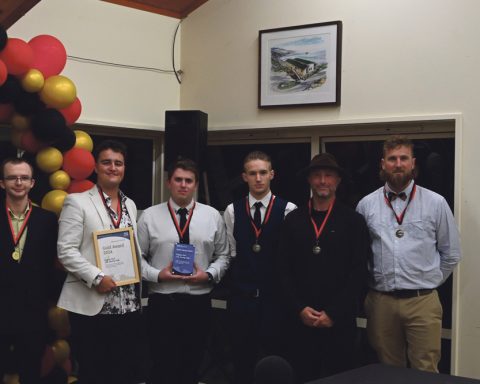

Taking out Champion Micro Brewery and picking up two golds, two silvers and one bronze at the recent NZ Beer Awards is an unexpected accolade for co-founders Bruno David, Matt Williams and Jake Gibbs.

They only entered the awards hoping to gain some feedback and, after only four years into their brewing journey, they gained confirmation from world class judges that they are hitting the mark.

“To submit five of our core range beers, one, the chocolate stout, which we only brewed once, and to get medals for all of those five beers was actually a bit mind blowing, because I was really just trying to look for feedback,” Bruno says.

Winning medals for every beer – golds for their Expeh! and Wakey Jakey, silvers for Pete’s Pilsner and Chocalot, and a bronze for the Raglan Pale Ale – put them in the running for micro brewery.

“Because we medalled across all of them, and we had two golds, we won the micro category, which is all breweries in New Zealand up to 50,000 litres. So yeah, I’m absolutely stoked to win that award, and it’s really unexpected. We actually had a few beers after that one,” he laughs.

The wins are testament to the time, effort, and finesse that goes into a Workshop brew.

Brewmaster Bruno is passionate about enhancing the flavour profiles of their core range of beers, as well as developing new one-off brews using seasonal produce from around Whāingaroa.

“We did a grapefruit IPA, with grapefruit off Pete’s tree. We’ve done an orange and guava sour with guavas from Pete’s place and oranges from mine. Just little cool things like that.”

They’re even producing non-alcoholic beverages, like kombuchas and sodas, all with local fruits growing mostly in Bruno’s garden.

A freshwater scientist turned brewmaster, Bruno applies a lot of core sustainability principles to brewing.

Water used to cool the beer is reused for washing and cleaning.

They’ve designed their own carbon dioxide recovery systems to capture CO2 released during fermentation and reuse it to carbonate the brews.

Spent grain and post-mashing becomes cattle feed for Dreamview Farm & Creamery and used to make sourdough at Raglan Artisan Bread.

“It’s really nice to involve the community. I take a sack of grain to Corinna and she gives me a loaf of bread.”

The off-licence brewery also minimises waste by letting people bring their own bottles to refill with beer fresh off the taps.

Although Workshop has only been open since 2019, the dream of opening a brewery in Raglan goes back close to 10 years when Matt and Jake dreamed up the idea while sipping beers at a Tofino brew bar in Canada.

Matt set about making the dream come true when he did an apprenticeship at Skinners, a large commercial brewer in the UK.

Back home in New Zealand and a chance conversation at a party introduced Bruno into the Workshop mix.

They started out using a small customised brewery pilot kit, which was capable of producing up to 100 litres of beer, and that’s where Bruno began experimenting with different styles of beer, along with different hops, yeast, barley, and water.

Bruno says the quality of Raglan’s town water is ideal for making beer, “Once we filter out the chlorine that the council puts in it, we get it back to its natural state. Essentially our beers are made with pure volcanic spring water which has a unique and favourable mineral profile for brewing”.

Other than the purchase of three specialised 2000 litre fermenters, the rest of the brewery equipment has been repurposed – a mill from a Cambridge farm to crush barley, dairy vats as brew kettles, the hot liquor tank was recovered from a farm gully and an old sink from Xtreme Zero Waste is now a keg washer/bottling bench.

Much of this ingenuity is down to Matt’s dad Pete who runs Raglan Engineering and is known around town as a fix-it man.

“We’ve built everything next door (at Raglan Engineering). It took us five years to piece all of the kit together.”

Bruno says it would have been cheaper to buy a turnkey brewery from China.

“The ethos that we’ve always had is around utilising existing materials that cost you labour and cost you time, but it has a story.”

There’s a sense of serendipity that the brewery is housed in the building on Park Drive. Back in the day, it was used to store the grain destined for Waikato Breweries back when goods came by ship over the Raglan bar.

“It’s kind of funny – the grain still comes here now by a different route, but it doesn’t leave – it gets converted to beer here,” Bruno laughs.

by Janine Jackson